On October 14, 2025, the Seminar on New Products and New Technologies of Soft Magnetic Components for New Energy Vehicles was successfully held in Huizhou. The event was hosted by the Strategic Alliance for Technological Innovation in the Electric Vehicle Industry (hereinafter referred to as the "Alliance") and co-organized by Shenzhen Click Technology Co., Ltd. (hereinafter referred to as "Click") and CITIC Metal Co., Ltd. (hereinafter referred to as "CITIC Metal"). Attendees of the seminar included Gu Jiye, General Manager of Cree; Wang Wenjun, Deputy General Manager of the Niobium Products Business Unit at CITIC Metal; Mariana Oliveira, Head of Nanocrystalline Technology at Companhia Brasileira de Metalurgia e Mineração (CBMM); Zhao Qian, Project Director of the Science and Technology Innovation Department at the China Society of Automotive Engineers (hereinafter referred to as "China SAE"); and over 130 representatives from whole-vehicle manufacturers, motor controller firms, OBC (On-Board Charger) providers, charging pile companies, soft magnetic component and material enterprises, as well as universities and research institutions.

.png)

Group Photo of the Seminar

First, Zhao Qian (Project Director of the Science and Technology Innovation Department of China SAE), Gu Jiye (General Manager of Click) and Guo Aimin (Chief Scientist of CITIC Metal) delivered speeches respectively.

Speech by Zhao Qian, Project Director of the Science and Technology Innovation Department of China Society of Automotive Engineers

Zhao Qian pointed out that the performance of soft magnetic materials and components is directly related to the energy efficiency, safety and reliability of the entire vehicle. High-performance electric drive systems and megawatt-level supercharging have put forward higher and more urgent requirements for soft magnetic components, making innovative breakthroughs in soft magnetic materials and component technologies crucial. This seminar focuses on core topics such as EMC simulation and testing technology, optimization of circuit topology and control algorithms, deepening of magnetic integration technology, prospects of solid-state transformers, and application of nanocrystalline components. The China Society of Automotive Engineers and the Alliance provide high-quality services for enterprises and the industry in multiple aspects to help accelerate the transformation and upgrading of the automotive industry.

Speech by Gu Jiye, General Manager of Shenzhen Cree Technology Co., Ltd.

Gu Jiye noted that as China's first listed company specializing in magnetic components, Cree has been deeply engaged in magnetic components and power supply products for over 30 years, with technological R&D as its core driving force. Through continuous technological breakthroughs to meet industry development needs, it has secured a significant market share in magnetic components within the automotive sector. This seminar, which brings together top-tier wisdom and cutting-edge experience from the automotive industry, is bound to inject new ideological momentum into the industry's development.

Speech by Guo Aimin, Chief Scientist of CITIC Metal Co., Ltd. (via video)

Guo Aimin stated that the development and application of nanocrystalline materials have long been a key focus area for CITIC Metal. The nanocrystalline-specific ferroniobium alloys it provides to users ensure the stable quality of nanocrystalline products. Going forward, CITIC Metal will continue to build a robust platform for technical cooperation among enterprises, downstream users, research institutions, and associations, establishing an "industry-university-research-application" industrial chain alliance. Leveraging CITIC Group's comprehensive industry background, resources, and overall influence, it will facilitate the continuous development of nanocrystalline material technologies and their better application in the new energy vehicle sector.

Subsequently, six guests delivered speeches, namely Liu Weiliang, Deputy Director of R&D at CRRC Times Electric Drive Technology Co., Ltd. (Hunan), Xia Zhengpeng, Chief Engineer of the Controller Development Platform at Wuxi Xingqu Technology Co., Ltd., Guo Junzhao, Supervisor of the R&D Institute at Dongfeng Motor Corporation, Wang Yun, Director of the Component EMC Office, EMC Department of China Automotive Engineering Research Institute New Energy Vehicle Inspection Center (Tianjin) Co., Ltd., Yuan Wenqi, Technical Head of the Magnetic Group, Power Drive Business Unit of United Automotive Electronics Co., Ltd., and Chong Magang, Manager of the Module Development Department at TGOOD New Energy Co., Ltd.

Liu Weiliang, Deputy Director of R&D at CRRC Times Electric Drive Technology Co., Ltd. (Hunan)

Liu Weiliang gave a speech entitled *Development Trends of Electric Drive Systems for New Energy Vehicles*. He pointed out that the demand for technological iteration of complete vehicles has driven the rapid development of electric drive system technologies, which are evolving towards higher power density, higher efficiency, higher voltage, higher safety and reliability, better quality, and lower costs. He focused on elaborating on the technological development context of motors, electronic controls, and gear transmissions from the perspectives of high power density and high efficiency.

Xia Zhengpeng, Chief Engineer of the Controller Development Platform at Wuxi Xingqu Technology Co., Ltd.

Xia Zhengpeng delivered a speech titled *Technical Fundamentals and Material Properties of Nanocrystalline Soft Magnetic Alloys*. He noted that with the improvement of multi-core MCU computing power and the increase in vehicle functions, the integration level of multi-in-one systems is becoming increasingly high. However, multi-in-one integration brings challenges such as electromagnetic compatibility, NVH (Noise, Vibration, Harshness), and high after-sales maintenance costs. The development trends of next-generation multi-in-one controllers include high performance, high integration, low cost, lightweight, and miniaturization. The 4.0-stage domain-integrated intelligent controllers will be based on a central computing architecture, featuring more concentrated computing power and enabling vehicles to achieve full intelligence and electrification.

Guo Junzhao, Supervisor of the R&D Institute at Dongfeng Motor Corporation

Guo Junzhao delivered a speech entitled Research and Application of Simulation Technology for Conducted and Radiated Emissions in Electric Drive Systems. He pointed out that the electric drive system is a significant source of electromagnetic interference in new energy vehicles. The trends toward higher speed, lighter weight, and multi-in-one integration of electric drive systems have posed severe challenges to the system's conducted emissions and radiated emissions. In the process of rectifying and reducing noise in conducted and radiated emissions, the characteristics of magnetic components play an important role. For example, a deep understanding of the electromagnetic properties of passive components such as common-mode inductors, differential-mode inductors, and magnetic beads is required.

Wang Yun, Director of the Component EMC Office, EMC Department of China Automotive Engineering Research Institute New Energy Vehicle Inspection Center (Tianjin) Co., Ltd.

Wang Yun gave a speech titled Electromagnetic Compatibility Test and Evaluation of Advanced Electric Drive Systems. He first introduced the dynamic updates of EMC standards for electric drive systems, noting that the electromagnetic compatibility section of GB/T 18488-2024 has been added to regulatory items. He then shared advanced EMC testing technologies, including EMC digitalization technology, EMC testing of electric drive systems under dynamic working conditions based on consumer driving scenarios, and EMC testing of electric drives under load for vehicle consistency. Additionally, he mentioned the implementation of high-quality power system certification, which evaluates power performance, energy efficiency, power safety, electromagnetic indexes, noise quality, and reliability.

Yuan Wenqi, Technical Head of the Magnetic Group, Power Drive Business Unit of United Automotive Electronics Co., Ltd.

Yuan Wenqi delivered a speech entitled Research and Application of Magnetic Integration Technology in On-Board OBCs. He stated that OBC magnetic components include filters, inductors, and transformers. Higher product competitiveness focuses on power density and cost, making the miniaturization and cost reduction of power magnetic components crucial. Magnetic integration technology is an important means to achieve miniaturization and cost reduction of power magnetic components. Magnetic integration is divided into multi-channel decoupling integration and multi-channel coupling integration. The challenges in applying magnetically integrated components include the selection of on-board magnetic core materials, heat dissipation issues, and magnetic core cracking problems.

Chong Magang, Manager of the Module Development Department at TGOOD New Energy Co., Ltd.

Chong Magang delivered a speech entitled Application of Magnetic Components in Charging Modules. He stated that the charging module is a core component of DC charging equipment, accounting for 50% of the total system cost, with development trends toward high power, high efficiency, and low cost. Magnetic components are the core carrier for energy conversion in charging modules and key parts affecting their technological development, accounting for 25% of the cost. Their development trends include aligning with the evolution of power topologies, achieving low cost and high efficiency through in-depth magnetic integration, and promoting the use of new magnetic core materials, thereby helping charging modules develop toward higher power density and higher efficiency.

On the afternoon of the 14th, five guests delivered speeches, including Cui Bin, Associate Researcher at the Department of Electrical Engineering, Tsinghua University; Zhou Zhengguo, Dean of the Research Institute at Shenzhen Cree Technology Co., Ltd.; Mariana Oliveira, Head of Nanocrystalline Technology at Companhia Brasileira de Metalurgia e Mineração (CBMM); Lu Zhichao, Professor at Beijing Jiaotong University; and Li Lijun, Head of Amorphous Business at Advanced Technology & Materials Co., Ltd.

Cui Bin, Associate Researcher at the Department of Electrical Engineering, Tsinghua University

Cui Bin gave a speech titled Research on Key Technologies of Large-Capacity Solid-State Transformers. A solid-state transformer is a power transformation device that contains power electronic converters and high-frequency isolation transformers, realizing voltage transformation, power transmission, and electrical isolation. It has many advantages such as high power density, small size, low weight, low noise, flexible control, and electrical isolation. He also introduced its applications and key technologies in DC transformers, medium-high frequency isolation transformers, data centers, new energy, and energy storage.

Zhou Zhengguo, Dean of the Research Institute at Shenzhen Click Technology Co., Ltd.

Zhou Zhengguo delivered a speech entitled Magnetic Integration Technology: Core Design Methods and Engineering Practices. Magnetic integration technology, pursued for higher power density, higher efficiency, better performance, and lower system cost, is an inevitable choice for modern power supply technology to develop toward miniaturization, high efficiency, and high reliability. However, magnetic integration also brings challenges such as complex design, poor flexibility, and potential mutual interference. He also introduced engineering practices including differential-common mode integrated inductors, dual-channel interleaved Boost inductor integration, three-phase inductor integration, LLC main transformer + resonant inductor integration, DAB main transformer + resonant inductor integration, three-phase DAB main transformer + resonant inductor integration, and three-phase LLC main transformer + resonant inductor integration.

Mariana Oliveira, Head of Nanocrystalline Technology at Companhia Brasileira de Metalurgia e Mineração (CBMM)

Mariana Oliveira gave a speech titled Application of Nanocrystals in Power Electronic Components. As a solution in the field of power electronics, nanocrystalline materials can be used in OBCs, DC-DCs, motor controllers, and charging piles. When used in EMI filters, compared with ferrites, nanocrystals have excellent properties such as high magnetic permeability, high saturation flux density, and stable magnetic permeability over a wide temperature range. When used in power transformers, they can significantly reduce the amount of magnetic materials compared with ferrites. Nanocrystalline magnetic rings can also be used to protect motor bearings and eliminate electromagnetic interference issues.

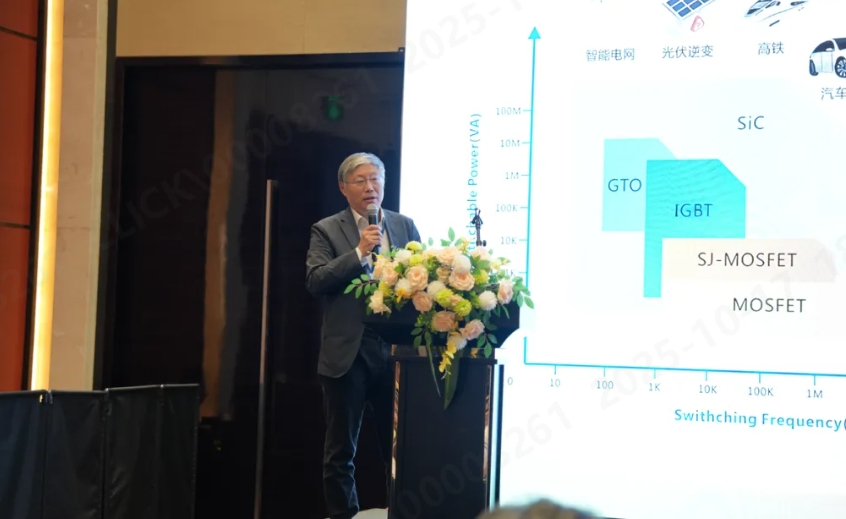

Lu Zhichao, Professor at Beijing Jiaotong University

Lu Zhichao delivered a speech entitled New Technologies and Application Research of Nanocrystalline Soft Magnetic Alloys. The rapid development of third-generation semiconductor switching devices has put forward new demands and challenges for soft magnetic materials and components, and nanocrystalline soft magnetic alloys have outstanding advantages in high-frequency applications. The magnetic permeability of nanocrystalline alloys (magnetic cores) can be regulated through magnetic field heat treatment and composition adjustment. A roll-to-roll Joule nanocrystallization treatment technology (RTRJS) has been developed, which can customize the magnetic permeability arbitrarily between 60 and 30,000, maintaining the inherent advantages of nanocrystals while expanding the application space.

Li Lijun, Head of Amorphous Business at Advanced Technology & Materials Co., Ltd.

Li Lijun gave a speech titled Development and Application of High-Frequency, High-Performance Nanocrystalline Ultra-Thin Strips for Electric Drive Systems of New Energy Vehicles. Ultra-thin nanocrystalline alloy strips have significant performance advantages: under 100kHz, the magnetic permeability of 10-12μm strips is increased from 40,000 to 60,000 compared with 14-16μm strips; under 40kHz and 600mT, the loss of 10-12μm strips is reduced by more than 15% compared with 14-16μm strips. In addition to new energy vehicles, he also introduced application cases of ultra-thin nanocrystalline alloy strips in household central air conditioners, wind power energy storage converters, and photovoltaic inverters.