With consumers' increasing demands for quality of life, the growing need for electronic products has driven continuous development in the switching power supply industry. However, due to dual pressures from upstream electronic components and downstream finished product costs, competition within the industry has intensified, gradually shrinking profit margins. Therefore, reducing costs while maintaining product quality has become a critical challenge for enterprises.

This article explores the cost-reduction process of a charger product from a design perspective, aiming to inspire further discussions and insights on cost efficiency.

The product in question is a power tool charger, competing directly with offerings from three rival companies, making cost control exceptionally stringent.

During the initial product development phase, the R&D team must evaluate not only material costs but also collaborate with manufacturing to optimize and simplify production processes for overall cost efficiency.

Different departments often have conflicting priorities, sometimes leading to intense disagreements. To balance these interests, the team engaged in thorough discussions, weighing factors such as material costs, manufacturing expenses, operational ease, and reliability. Key departmental requirements were summarized as follows:

R&D: Minimize material costs while ensuring stable electrical performance and ease of production.

Manufacturing: Reduce labor dependency, minimize assembly time, simplify operations with foolproof designs, and eliminate the need for extensive operator training.

Engineering: Minimize equipment and fixture requirements while ensuring maintainability and ease of operation.

Early-stage development required extensive supplier input to gather detailed data. The more comprehensive the information, the more accurate the cost assessment. However, tight project timelines demanded rapid decision-making, placing significant pressure on the R&D team.

To avoid indecision, the team employed the EMV Decision Tree method to evaluate four design alternatives.

.png)

Note: In the decision tree, Option 2 and Option 4 initially assumed a 2% defect rate, increasing repair costs. However, with operator training and improved proficiency, the defect rate was projected to fall below 0.3%.

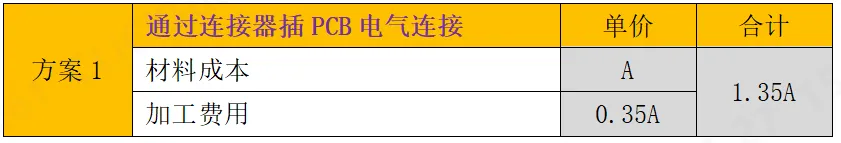

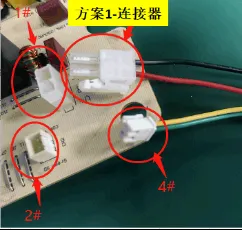

Connection method: PCB and wiring harness linked via connectors (4 connectors total).

Pros: Foolproof design, eliminates assembly errors.

Cons: Higher connector costs, increased labor time, and potential reliability risks.

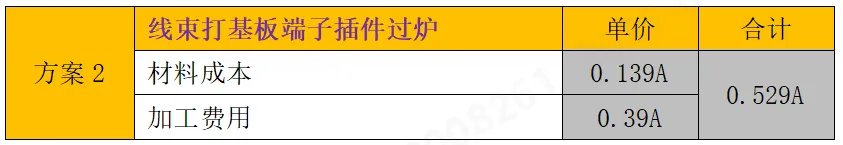

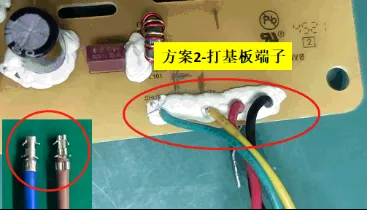

Connection method: Harness terminals directly inserted into PCB (no connectors).

Pros: Secure electrical connection, no floating issues.

Cons: Requires precise color-coded insertion, increasing assembly difficulty.

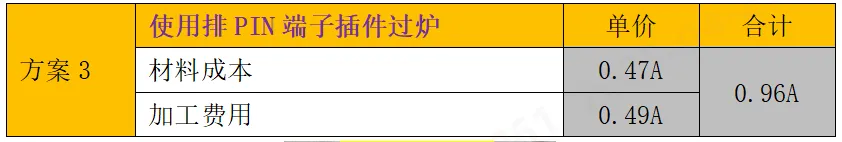

Connection method: Ribbon-pin terminals for PCB connection.

Pros: Foolproof design, minimal floating risk.

Cons: Higher harness processing costs, requires fixtures to prevent terminal misalignment.

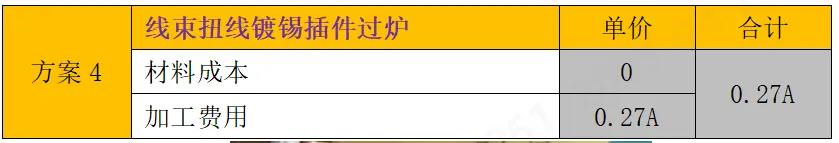

Connection method: Twisted & tinned wires soldered directly to PCB (simplest method).

Pros: Lowest material cost (no connectors needed).

Cons: Risk of floating connections, requires soldering fixtures, and depends on operator precision.

After comprehensive evaluation, Option 4 was selected. Compared to the initial prototype (Option 1), this solution achieved an 80% cost reduction, significantly exceeding the cost-saving target.

This case demonstrates how structured decision-making tools like EMV analysis can guide cost-optimization strategies while balancing reliability and manufacturability.

(Note: Technical terms such as "floating connections)" , "floating connections" , and "fixtures" have been localized appropriately for clarity in an engineering context.

Would you like any refinements for specific audiences (e.g., deeper technical explanations for engineers or simplified summaries for management).